rockwell brinell hardness test|brinell hardness test explained : mail order Various methods are used to measure the hardness of a material. Brinell hardness and Rockwell hardness are two of the most common methods used for this purpose. In this article, we will discuss these two hardness testing .

16 de jan. de 2024 · A incrível ascensão do criador de conteúdo adulto e revelação sobre suas gravações.FRANCIS SIMASINSTAGRAM / FACEBOOK: @francissimasrealTIKTOK: .

{plog:ftitle_list}

webCdzinha passiva você confere aqui nos grupos +18 do telegram com vários vídeos de putaria rolando todos os dias em nossos canais, veja a seguir e divirta-se ! Vazaram a sacanagem de várias mulheres casadas dando em cima dos seus amantes.

1L Differential Scanning Calorimeter convenience store

rockwell vs brinell hardness test

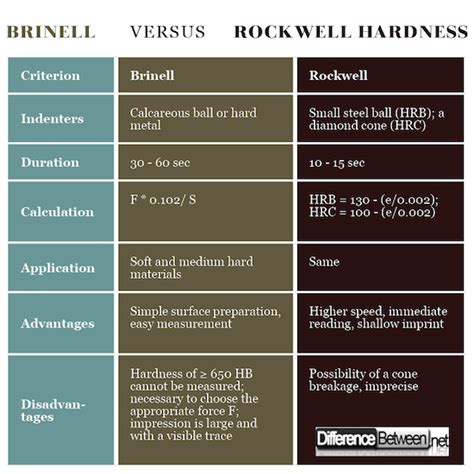

In this article, our seasoned expert, Lee Mangham, will guide you through the differences between the Brinell and Rockwell hardness tests, including their methods, advantages, differences, and practical significance in evaluating .Summary of Brinell Verses Rockwell Hardness. The Brinell and Rockwell methods fall into the group of statistical methods of hardness testing. Each method has its unique purpose, .In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. The Brinell Hardness Test method is the .

disadvantages of rockwell hardness test

The Brinell hardness testing method is mainly used to check the hardness of soft and medium-hard materials with rough and coarse surfaces. At the same time, the Rockwell .

The Rockwell hardness test method can easily pass as the most applied form of testing for material hardness majorly due to benefits like its fast-testing procedures and its high accuracy. .Various methods are used to measure the hardness of a material. Brinell hardness and Rockwell hardness are two of the most common methods used for this purpose. In this article, we will discuss these two hardness testing .

The three most well known and widely used hardness tests for metals today are Brinell, Rockwell, and Vickers. Here are the basic differences explained.If you need a quick, non-destructive measurement for a variety of materials in a manufacturing setting – the Rockwell hardness test is suitable. For softer materials or materials with coarse microstructures – the Brinell hardness test .

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test .To wrap up, knowing the best-suited hardness test of the three, Rockwell, Brinell, and Vickers, for your hardness test will require that you understand the determining criteria for employing any hardness test. In the final analysis, the type of material and the environment where the test will take place will significantly determine the best . Brinell Hardness. Relatively high loads are applied to parts via a tungsten carbide ball in this method. Unlike with Rockwell testing, Brinell tests measure the diameter of the indentation made by the ball, not the depth. A 10mm ball with an applied load of 3,000 kgf is most common for Brinell testing. Brinell tests are ideal for castings and .

The Brinell hardness test typically uses a higher load than the Rockwell hardness test. The way the results are reported is also different. Brinell hardness is reported as the Brinell hardness number (BHN), which is calculated by dividing the applied load by the surface area of the resulting indentation.The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters.Difference between, Brinell,Rockwell and Vickers Hardness Test What is Hardness? Hardness is the property of a material that enables it to resist plasticHardness Methods: The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y

Brinell Indentation Diagram. In the standard method of the Brinell Hardness Test, we use 250 to 500 kg of load for soft material and 500 to 3000 kg of load for hard material such as steel and iron.What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load).The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .

ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .

High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of the resistance .Learn how to use Brinell hardness test units and testing machines to quickly and accurately assess large samples with a coarse or inhomogeneous grain structure – with knowledge and insight from Struers, the world’s leading .

Rockwell Hardness Test. The Rockwell hardness test is a widely used method for determining material hardness, especially in high-volume testing environments, due to its speed, simplicity, and efficiency. It provides direct hardness readings without the need for additional calculations, making it ideal for routine quality control. Hardness testing is a crucial method for evaluating the mechanical properties of materials. It helps determine a material's resistance to deformation, wear, and scratching. Among the various hardness testing . Metode Hardness Test Rockwell berbeda dengan Brinell dan Vickers. Pada uji kekerasan Rockwell tidak melakukan pengukuran tapak tekan secara manual, pengukuran langsung dilakukan oleh mesin dan langsung menunjukkan nilai hardness dari bahan yang diuji, nilai ini dapat dilihat pada dial indicator.Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from Struers, the world’s leading materialographic and metallographic experts. . Knoop, Brinell and Rockwell automatic .

Multiple test force generation for Rockwell, Rockwell Superficial and Brinell hardness. Dolphin-nose indenter arm for easy reach of interior (min. ø40mm/ø22mm*) and exterior surfaces. Real time electronic test force control for accurate loading. This .A variety of hardness-testing methods are available, including the Vickers, Brinell, Rockwell, Meyer and Leeb tests. Although it is impossible in many cases to give an exact conversion, it is possible to give an approximate material-specific comparison table for steels .

difference between rockwell and brinell

The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone .

difference between hrb and hrbw

What is Rockwell Hardness? Similar to Brinell hardness, Rockwell hardness is also used to understand what the hardness of material is in numerical terms. This is done through the use of a Rockwell hardness test and a Rockwell hardness scale. The exact method can be found in ASTM E18.Hardness Testing Basics; Rockwell Hardness Testing; Brinell Hardness Testing; Vickers Hardness Testing; Knoop Hardness Testing; Case Depth Hardness Testing; PRODUCTS. Rockwell Hardness Testers. Indentron Rockwell Hardness Tester; Versitron Rockwell Hardness Tester; Rockwell Accessories; Brinell Hardness Testers. NB3010 Series Brinell .With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface serves as a measure of the hardness. Vickers hardness te.

While the Rockwell hardness test has its uniqueness, its accuracy is also guided by some critical factors you need to consider before engaging in this test method. Rockwell Testing Machine – The machine itself is one critical consideration for an accurate Rockwell test result. And though the Rockwell test is often seen as very easy and quick .

Thermo gravimetric analyzer (TGA) convenience store

Rockwell Hardness (HRC, HRB) to Brinell Hardness (HB or BHN) Conversion. Hardness is very important for producing rough metal castings, heat treatment and machining process. Rockwell Hardness (HRC and HRB) and Brinell Hardness (HB or BHN) are most commonly used for steel and iron castings. Although there is no accurate conversion tables and .

Differential Thermal Analyzer convenience store

webHow thousands of gangs in all over 50 states and around the world and over 150 countries changed and reshaped our history.

rockwell brinell hardness test|brinell hardness test explained